Factory Automation

VISSER AND VIVI ARE NOW THRIVING TOGETHER AS VISCON PLANT TECHNOLOGY

Factory Automation

This page is being translated by Google Translate

You're invited! Stay up to date with our latest company news, customer stories and job vacancies.

Read more →

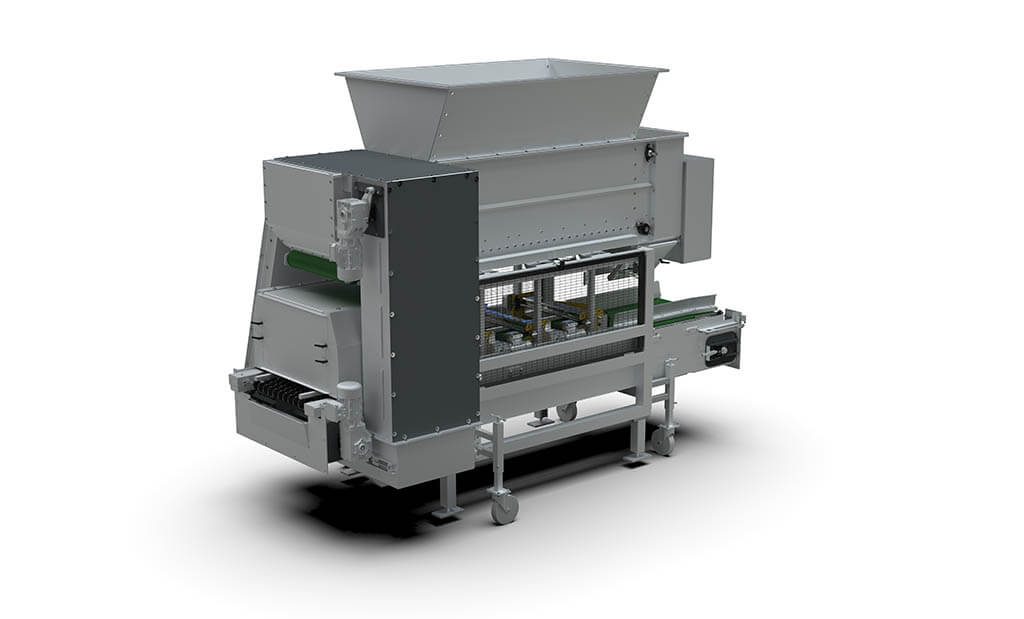

The Versa Filler is the most advanced and versatile filler. It is fully adjustable to your container, plug diameter, filling density, and required capacity. The Versa Filler is specialized in filling plug trays with high speed, perfect soil compaction, and a homogeneous filling result.

The Versa Filler is the most advanced and versatile filling machine on the market. With a clearance of 400 mm high and 600 mm wide and the capability to fill long-side leading, it is suitable for filling any plug tray. The Versa Filler can fill up to 500 trays per hour and can achieve a very high soil compaction.

A perfect filling result is guaranteed by utilizing five exchangeable substrate compressing processes:

1. Rubber compression roller for optimal soil compaction.

2. Second rubber compression roller for extremely high soil compaction.

3. Driven dibbling plate unit

4. Spiral rotating brush pulls any excess soil for a clean finish.

5. Second spiral rotating brush for a clean finish and uniform result.

All internal components are height adjustable and have manually adjustable speed control to give you the fill you require. 10 Air nozzles are used for soil removal, making for a clean operation. This Versa Filler is service friendly as all internal components are easily interchangeable.

The Versa Filler features a 1000-liter capacity hopper over the transport conveyor to save space and make it perfectly suitable for overhead feed systems. A hopper extension is optional to increase the volume to 1850 liters. The soil elevator has a manually adjustable soil flow and has an improved design to produce less noise, less wear, and less tear.